Kingrail Parts produces rubber grade crossing systems for new railway projects, railway interface upgrade projects, major and rural gravel roads, and railway depots.

Our rubber crossing systems can comply with UIC, BS, JIS and other standards.

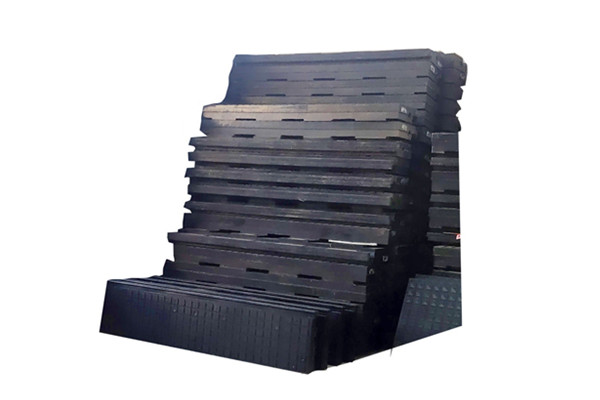

1. Full Depth Heavy (HD) Crossing Systems

Our Heavy Duty Rubber Grade Crossing System is the most durable full depth rubber crossing system. The heavy duty system is made of 100% pure rubber and is designed to withstand repeated punishment at high speeds, heavy loads. The product's durability, long life and low maintenance requirements make it ideal for most applications. Heavy duty panels can be reused when intersections are reconfigured or closed. Heavy duty panels can be used with most rail fasteners.

Technical Data:

Panel length: 3 feet

Panel Height: Accommodates 90# to 141# Rail Weight

Dashboard width: 58 1/2 inches

Field panel width:

31" (10ft tie)

25" (9ft tie)

22" (8'6" tie)

Rubber:

Type: Virgin SBR

Tensile Strength: 2,000 psi

Hardness: 65 ± 5 Shore A

Elongation: 400%

Fastener:

Wood Screw, 3/4″ x 7 1/2″ (galvanized)

Carbon steel

Tensile Strength 120,000 psi min.

Pullout Resistance +13,000 lbs

2. Reinforcement Crossing Systems

The ramp crossing system consists of a raw rubber panel reinforced with 1/4" corrugated steel sheet mounted on pressure treated longitudinal hardwood spacers.

Raw rubber absorbs the shock of concentrated loads such as forklifts, while steel plate provides the strength to carry heavy loads. Steel Reinforced systems are ideal for low MGT, heavy duty truck use such as intermodal yards and private industry.

Technical Data:

Panel length: 3 feet

Panel Length: Accommodates 20# to 141# rails

Dashboard width:

24 1/2" (9ft tie)

21 1/2" (8'6" tie)

Rebar:

Type: 1/4" Corrugated Steel (C1008)

Rubber:

Type: Virgin SBR

Tensile Strength: 2,000 psi

Hardness: 65 + 5 Shore A

Elongation: 400%

Fastener:

wood screw, 5/8 x 10 1/2 in.

Carbon steel

Tensile Strength 120,000 psi minimum

Tensile Strength + 13,000 lbs

3. Virgin Rubber Crossing Systems

Virgin Rubber Systems are made from 100% virgin rubber. Rubber crossing systems protect the rail structure by absorbing traffic shock loads, provide positive flanged passages that control surface water runoff, and prevent asphalt cracking at the rail interface.

The virgin rubber crossing systems are designed with several advantages over other rail sealing products. Panels are easy to operate and install. The larger surface area of the rubber crossing systems provides better cushioning for the rails and is self-supporting. The durability of 100% virgin rubber makes rubber crossing systems ideal for any traffic situation. Either asphalt or concrete can be used in combination with rubber crossing systems.

The virgin rubber crossing panels are designed to accommodate heavy traffic when rail seals are specified instead of full-width rubber crossings. Examples include road intersections, intermodal yards, docks and industrial parks.

Technical Data:

Panel Length: 7 1/2 feet, 8 feet

Panel Length: Accommodates 90# to 141# rails

Rubber:

Type B: Virgin SBR

Tensile Strength: 2,000 psi

Hardness: 65 ± 5 Shore A

Elongation: 400%

Contact us

Please contact us for more information and quotations.

Inquiry Now