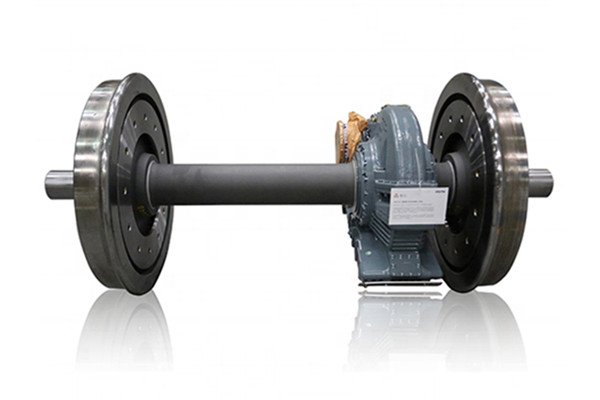

Kingrail Parts is a professional crane wheel manufacturer in China. We can produce overhead crane drive wheels in various sizes.

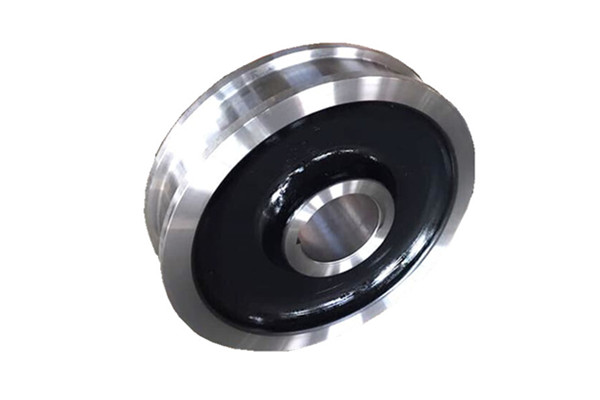

We use materials such as 65Mn or 42CrMo to make drive wheels. Our crane wheel production process is forging or casting.

Specification:

| Type: | Forging Wheel/Casting Wheel |

| Application: | Crane,trolley,transfer car,heavy duty industry,Port crane,Steel factory etc |

| Material: | 4140/SCM440/42CrMo,ssw-QIR/65#steel,65Mn,50SiMn,QT800 |

| Dimension: | Φ250, Φ350, Φ400, Φ500, Φ600, Φ700, Φ800, Φ 1000, Φ 1200 or as your require |

| Process: | Forging/Casting |

| Quality Control: | UT,MT,RT,PT,chemical composition test,mechanical property test,etc. |

| Heat Treatment: | Quenching and Tempering |

| Quenching Depth: | no less than 20mm |

| Coating: | Black Oxide+Rust-proof oil |

| Inspection: | Besides our in-house inspecion, you could also choose a third party inspection |

| Standard: | ASTM, ASME, DIN, JIS, ISO, BS, API, EN,GOST,etc |

| Certificate: |

1, Raw material certificate(material chemical compositon) 2, Heat treatment sheet report 3, Dimension inspection report 4, UT/MT test report |

| Packing: | Seaworthy plywood packaged on steel pallets or as customer's request |

| Delivery Date: | 15~30 working days |

| Competitive Advantage: | Quality control and management to the whole produce process, including ingot smelting,forging, heat treatment, machining and strictly final inspection prior to delivery. |

We can customize overhead crane drive wheels according to customer specifications and requirements

Contact us

Please contact us for more information and quotes.

Inquiry Now