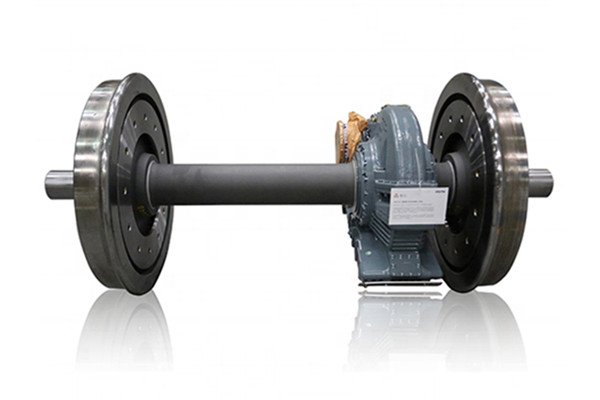

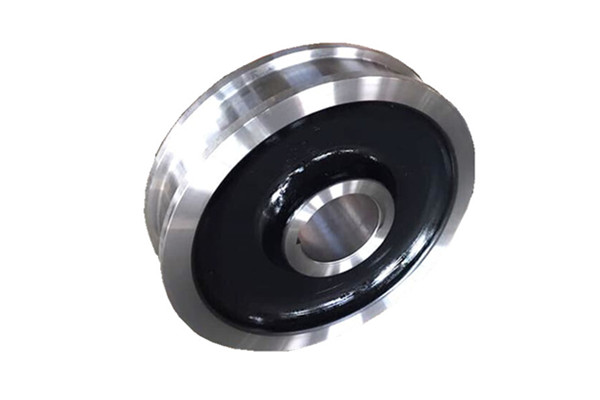

As a professional crane wheel manufacturer, Kingrail Parts can produce eot crane wheels in various sizes.

We use materials such as 65Mn or 42CrMo to make crane wheels. Our Eot crane wheel production process is forging or casting.

Specification:

|

Items |

Bearing |

Gear Teeth |

Materia |

HRC |

Wheel Load |

Square Bar |

|

GW95PW95 |

6203Z |

M3.5x25T |

S45C |

50±5 |

1000 |

32 |

|

GW120PW120 |

6206Z |

M3.5x32T |

S45C |

50±5 |

1600 |

32 |

|

GW150PW150 |

6306Z |

M4x35T |

S45C |

50±5 |

2100 |

32 |

|

GW180PW180 |

6308Z |

M4x42T |

S45C |

50±5 |

3200 |

38 |

|

GW198PW198 |

6308Z |

M4x 47T |

S45C |

50±5 |

4900 |

38 |

|

GW250PW250 |

6309Z |

M4x60T |

S45C |

50±5 |

5700 |

44 |

|

GW280PW280 |

6310Z |

M4x67T |

S45C |

50±5 |

8100 |

44 |

|

GW300PW300 |

6311Z |

M4x73T |

S45C |

60±5 |

8800 |

44 |

|

GW345PW345 |

6311Z |

M4x84T |

SC49 |

45±5 |

9700 |

55 |

|

GW430PW430 |

6314Z |

M6x69T |

SC49 |

45±5 |

15000 |

55 |

|

GW545PW545 |

6316Z |

M6x88T |

SC49 |

45±5 |

19000 |

63 |

Size:

|

Model |

A |

B |

C |

E |

F |

G(中) |

H |

J |

K |

L |

Oty |

M |

Weight |

|

GW95 |

95 |

70 |

50 |

85 |

170 |

17 |

185 |

9 |

9 |

5 |

2 |

15 |

13 |

|

PW95 |

75 |

2 |

|||||||||||

|

GW120 |

120 |

95 |

50 |

85 |

170 |

30 |

185 |

9 |

9 |

5 |

2 |

15 |

21 |

|

PW120 |

75 |

2 |

|||||||||||

|

GW150 |

150 |

120 |

50 |

90 |

185 |

30 |

200 |

9 |

9 |

5 |

2 |

20 |

37 |

|

PW150 |

75 |

2 |

|||||||||||

|

GW180 |

180 |

150 |

60 |

100 |

185 |

40 |

200 |

9 |

9 |

5 |

2 |

20 |

57 |

|

PW180 |

85 |

2 |

|||||||||||

|

GW198 |

198 |

170 |

60 |

105 |

185 |

40 |

200 |

9 |

9 |

5 |

2 |

20 |

72 |

|

PW198 |

90 |

2 |

|||||||||||

|

GW250 |

249 |

220 |

70 |

115 |

275 |

45 |

290 |

13 |

13 |

10 |

2 |

25 |

136 |

|

PW250 |

100 |

2 |

|||||||||||

|

GW280 |

280 |

250 |

70 |

115 |

275 |

50 |

290 |

13 |

13 |

10 |

2 |

25 |

175 |

|

PW280 |

100 |

2 |

|||||||||||

|

GW300 |

300 |

270 |

70 |

120 |

275 |

55 |

290 |

13 |

13 |

10 |

2 |

25 |

222 |

|

PW300 |

105 |

2 |

|||||||||||

|

GW345 |

345 |

300 |

75 |

140 |

285 |

55 |

300 |

13 |

13 |

10 |

2 |

40 |

319 |

|

PW345 |

110 |

2 |

|||||||||||

|

GW430 |

430 |

400 |

80 |

150 |

285 |

70 |

300 |

13 |

13 |

10 |

2 |

40 |

542 |

|

PW430 |

120 |

2 |

|||||||||||

|

GW545 |

545 |

500 |

80 |

150 |

285 |

80 |

300 |

13 |

13 |

10 |

2 |

40 |

872 |

|

PW545 |

120 |

2 |

Manufacturing process:

1. Drawings 2. 3D Modeling 3. FEM Analysis 4. Heat Treatment 5. Rough Maching 6. Bank Wheel 7. Finish Maching 8. Hardness Testing 9. Assembling

Contact us

Please contact us for more information and quotes.

Inquiry Now